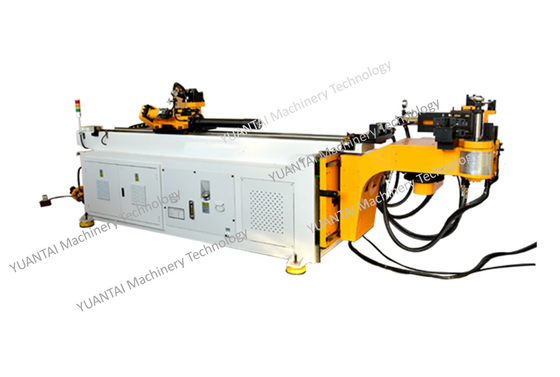

CNC38RET+RBE-4A Tube Bender Tail Bend Extension Booster Suitable For Stainless Steel Pipe

CNC38RET+RBE-4A Tube Bender

This is a fully automatic CNC pipe bending machine, forming one time, with multiple servo motors, and bending more accurately.

Advantages of equipment use

1, Automatic tube bending machine workstation, Tube forming in one time .

2, Reduce labor ,saving labor cost.

3, Two automatic feeding machines each feed the tube bender automatically, and a robot loads and palletizes the two tube benders at the same time.

4, The whole process all is controlled by PLC , with touch screen man-machine interface, the efficiency is improved wholely.

5, Automatic Identification of tube welds to make tube Bend Machine avoid Weld seam.

6, Use Industrial Robot for loading and unloading stacking.

Main technical parameters of the equipment

| machine characteristics |

|

main technical parameter |

|

| (1) Electical servo bending |

Max capacity |

round tube/iron tube( S=40kgf/mm ) |

38.1x1.8t |

| (2) Imported servo motor and reducer |

Round tube/non iron metal tube( S=25kgf/mm ) |

38.1x1.2t |

| (3) Independent R & D software system |

Round tube /stainless steel tube( S=60kgf/mm ) |

38.1x1.2t |

| (4) 1-5 layer die optional |

Square tube/Metal Tube( S=40kgf/mm ) |

30x1.5t |

| (5) 11 axis full motor type optional |

Bending radius |

25~150mm |

| Push-bending type, bending radius7D |

Servo bending axis |

precision |

±0.05 |

| |

max speed |

166°/sec |

| |

Servo material feeding axis |

precision |

0.05mm |

| |

max speed |

1200mm/sec |

| |

Servo tube rotate axis |

precision |

0.05 |

| |

max speed |

220°/sec |

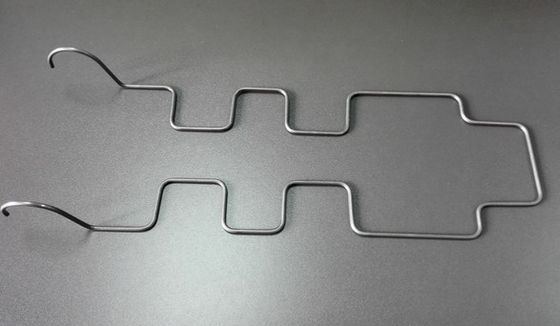

Applications:

Auto,motorbike,aircraft,bicycle,kids bike,fitness equipment,furniture,outdoor equipment,air conditioner,food machinery,nulcear tube such as reactor,evaporator and heat exchanger.

Machine characteristics:

1. Automatic 3D simulation function for tube-forming is selected as required.

2. An automatic error-fault detecting function is provided,and the errors and faults are displayed on the screen,so that the operator can much easily troubleshoot.

3. Automatic 3D simulation function for detecting interferring position is selected as required.

4. All processing data are inputted by the touch screen.

5. Based on the change of materials,each curve is set with a compensation value,a speed and a demoulding gap.

6. The feeding mode comprises the clamping feeding mode or the direct feeding mode which is selected as required.

7. The X.Y.Z coordinate can be automatically switched into the Y.B.C processing values.

8. After the data are compiled,the data is protected by a key,so that the data are prevented from any modification.

9. A feeding cart’s feeding position,safety position,wheel mode interfering position and guided mode interfering position are set,so that a hand wheel pulse wave generator can be finely tuned,the position can be automatically remembered,and the error caused by the manual measurement and the loss caused by the feeding cart bumping the machine are eliminated.

10. The feeding shaft will perform automatic detection before acting,so that the feeding shaft is avoided from bumping the machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!