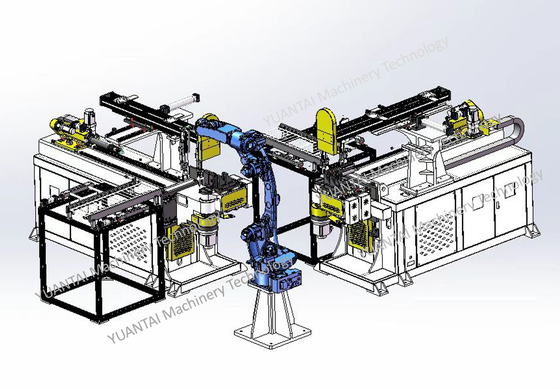

| machine characteristics | | main technical parameter | |

| (1) Electical servo bending | Max capacity | round tube/iron tube ( S=40kgf/mm ) | 18x1.6t |

| (2) Imported servo motor and reducer | Round tube/non iron metal tube

( S=25kgf/mm ) | 20x2.0t |

| (3) Independent R & D software system | Round tube /stainless steel tube

( S=60kgf/mm ) | 18x0.8t |

| (4) 1-6 layer die optional | Square tube/Metal Tube

( S=40kgf/mm ) | 15x15x1.2t |

| (5) 11 axis full motor type optional | Round bar( S=40kgf/mm ) | 8 |

| | Max capacity | precision | ±0.05 |

| | max speed | 180°/sec |

| | Servo material feeding axis | precision | 0.05mm |

| | Max speed | 1200mm/sec |

| | Servo tube rotate axis | precision | 0.05 |

| | Max speed | 300°/sec |

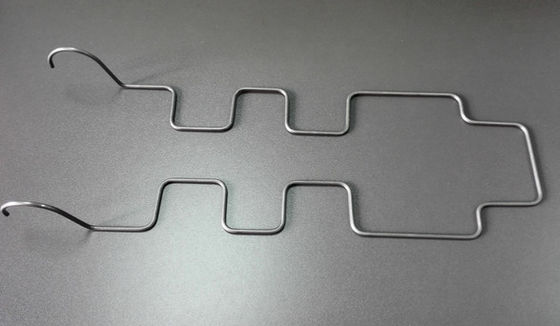

Recommended application industry:

Auto,motorbike,aircraft,bicycle,kids bike,fitness equipment,furniture,outdoor equipment,air conditioner,food machinery,nulcear tube such as reactor,evaporator and heat exchanger

Features of pipe bending machine:

1. Automatic 3D simulation function for detecting interferring position is selected as required.

2. All processing data are inputted by the touch screen.

3. Based on the change of materials,each curve is set with a compensation value,a speed and a demoulding gap.

4. Each curve of one tube can be programmed with five action sequences and ten-stage speeds,so that the processing efficiency is improved,and the interference point is reduced.

5. Chinese/English language are switched to display on the touch screen,and customers can also purchase the machine installed with other languages.

6. The feeding mode comprises the clamping feeding mode or the direct feeding mode which is selected as required.

7. The X.Y.Z coordinate can be automatically switched into the Y.B.C processing values.

8. After the data are compiled,the data is protected by a key,so that the data are prevented from any modification.

9. The electric control system is equipped with a heat exchanger for automatic heat dissipation;if necessary,a numerical control type refrigerator can be additionally bought,so that the life span of the electric control system is ensured.

10. An automatic oil charging system is installed to reduce friction of the bending tube.It prolongs the lifetime of the core rod and improves the quality of the bended tube.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!