| machine characteristics |

|

main technical parameter |

|

| (1) Electical servo bending |

Max capacity |

round tube/iron tube

( S=40kgf/mm ) |

89x2t |

| (2) Imported servo motor and reducer |

Round tube/non iron metal tube

( S=25kgf/mm ) |

89x4t |

| (3) Independent R & D software system |

Round tube /stainless steel tube

( S=60kgf/mm ) |

76x1.8t |

| (4) 1-6 layer die optional |

Square tube/Metal Tube

( S=40kgf/mm ) |

60x60x2.6t |

| (5) 11 axis full motor type optional |

Round bar

( S=40kgf/mm ) |

38 |

| Push-bending type, bending radius7D |

Servo bending axis |

precision |

0.05 |

| RBE strongly back push bending, minimum bending radius is 1D |

max speed |

65°/sec |

| |

Servo material feeding axis |

precision |

0.05mm |

| |

max speed |

750mm/sec

RBE: 150mm/sec |

| |

Servo tube rotate axis |

precision |

0.05 |

| |

max speed |

180°/sec |

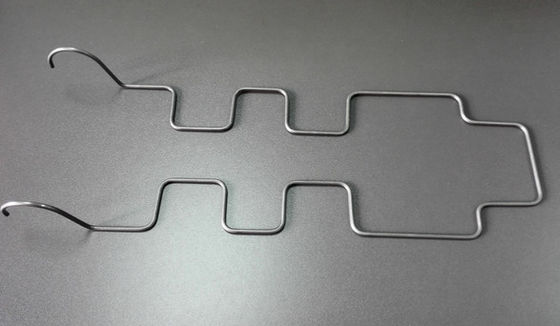

Adapted material:steel pipe, stainless steel, copper pipe, aluminum pipe etc.

Recommended application industry:

Automobile fittings ( oil pipe for brake, muffler, seats), motorcycle, healthy equipment, air-conditioning,bicycle, steel furniture, sanitary wares and so on.

Features of pipe bending machine

1. Automatic recognition of power in machine and work piece, the processing is both quick and good.

2. Slow returning core, boosted by barrow, imporving the apprearance of the angle.

3. The whole operation is in the computer, simple, quick and correct.

4. Picturized programming system: draw and modify on the stereo pipe image on the screen, makes the operation simple,quick and correct.

5. Rebound test: comparison test on the features of lots of pipe materials.

6. Single-step debugging function- a careful observe on the deformation of the pipe material during the trail manufacture of dies.

7. Automatic drawing of the graphics of dies-clear help to develop new products.

8. Over-all inspection: hydraulic/electrical circuit/ driving systems, adsence of phase in motors/inversion,voltage, temperature, oil pressure, and automatically diagnose the troubles.

9. Passwords, keys, working hours/ recordings of quantities, are applied to management of production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!